Anyone in need of capsules for clinical trials?

Kragerø Tablettproduksjon AS is happy to assist with the production of non-sterile pharmaceutical formulations for use in clinical trials.

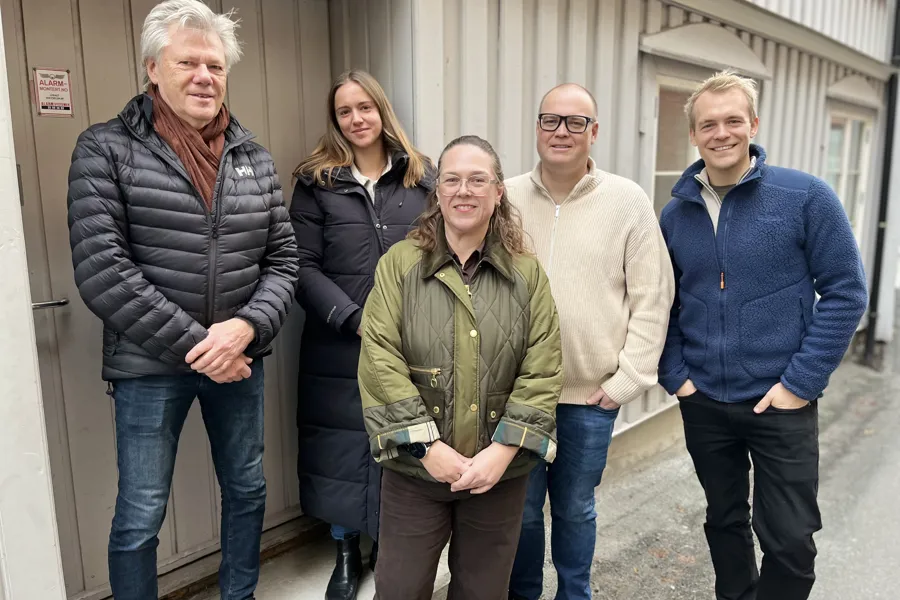

- As of today, we are producing for around 20 ongoing clinical trials, mainly commissioned by clinicians at Norwegian hospitals. Among other things, we manufacture for trials in rheumatology and ALS, and the active substances dexamfetamine and ambroxol. But we also produce for a trial in the United Kingdom and one in Uganda, and we are happy to take on production of investigational medicines for the industry as well, says general manager and owner Ragnar Salmén.

He shows us around the facilities together with Quality Manager Hilde Kilen, Assistant Quality Manager Marte Brødsjø, and Operations Manager Kåre Gunnar Kilen.

The main task of the nine employees at Kragerø Tablettproduksjon (Kratab) is to produce tablets for Serviceproduksjon AS, owned by the Norwegian Pharmacy Association (Apotekforeningen). This involves small-scale production of medicines that the pharmaceutical industry does not manufacture, but that Norwegian patients nonetheless need. Kragerø Tablettproduksjon produces around 20 such NAF products, which are sold exclusively in Norwegian pharmacies. These range from thyroid medications to vitamin B.

Expanded for clinical trials

In recent years, however, they have also expanded to produce tablets and capsules for clinical trials.

The production takes place under approved GMP conditions, both in Apotekgården in the centre of Kragerø and in a newer production and storage facility situated a little further uphill.

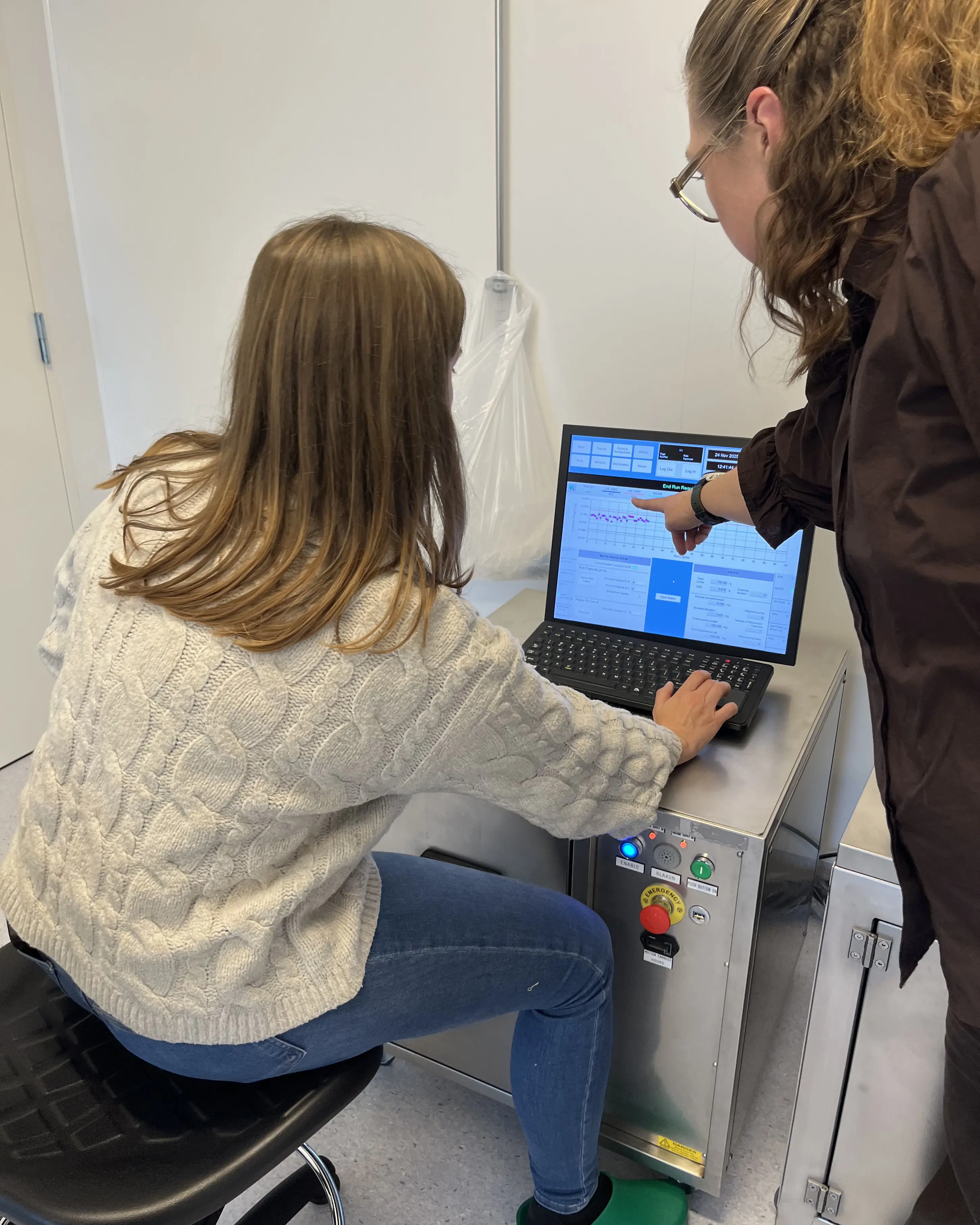

Earlier this year, they invested in a brand-new dosing instrument, delivered in October. The dosing instrument makes it possible to automate the weighing of very small quantities of powder directly into capsules.

- We call it the world’s most advanced saltshaker, says Hilde Kilen, showing how the active ingredient in powder form is dispensed in highly precise amounts through a funnel with tiny holes, and into one half of the capsule.

The capsule sits on a scale that registers powder down to the microgram and, via a feedback loop, controls the supply of powder into the capsule. The other half of the capsule is then put in place before it is released into a waiting bowl.

- The capsule can be filled with active ingredient only (API), meaning no excipients. This offers a major advantage in development and early clinical phases, as it eliminates time- and cost-intensive processes like validation and method development, she explains.

They have also previously produced capsules for similar purposes by hand, but this is far more time-consuming and less precise. The capsule machine cost just under NOK 5 million and was partially funded by both Innovation Norway and the Telemark Development Fund.

- In practice, the capacity is 300–400 capsules per hour, and at present we can produce capsules in size 0 and size 2, with anything from 0.250 mg up to 100 mg API. This is most relevant for phase 1 and phase 2 trials, explains Kilen.

Kragerø Tablettproduksjon AS recently adopted a new logo and will gradually rebrand itself simply as Kratab. They show that size is not what matters: their revenues increased to NOK 33.1 million in 2024, up from NOK 28.6 million the previous year.

Kratab emerged from the Kragerø Pharmacy in 2002 and, as a former part of the pharmacy, traces its roots back to 1770, but has adapted well to changing times and needs.

- As far as we know, there’s not anyone else with a capsule machine like this who also offers production services on demand in this way. Not in Northern Europe, at least, says Salmén.

- So you’re actually quite unique?

- Yes, we’re quite unique, and we hope that anyone in need of this kind of service will now become aware of us. In addition, we’re a small company and can adapt quickly, Kilen reminds us.